scrutiny

coventry

|

1 of 16

Mon 6th May 2013 4:46pm

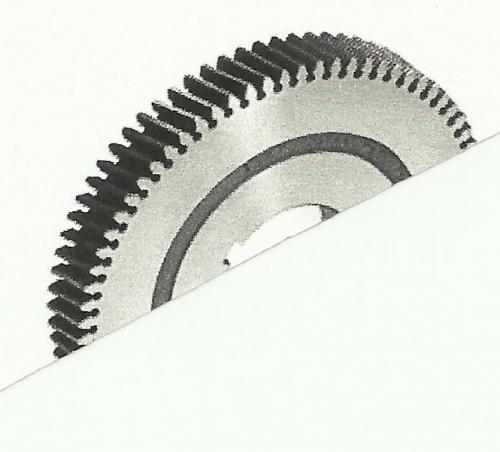

I worked at this factory for a very happy 12yrs 11mths. I was wondering if anyone can recognise this machine? There were 10 of them, of which I worked 2. This one is currently for sale in America.

|

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

LdeMain

Nuneaton, Warks

|

2 of 16

Wed 8th May 2013 8:54pm

Sorry, I have no recollection of the machine. My dad used to do some work at PGM, he was self-employed but used to service and calibrate the metal hardness testing machines, his name was Steve de Main. I'd love to know if anyone remembers him!

Leanne |

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

scrutiny

coventry

Thread starter

|

3 of 16

Thu 9th May 2013 7:13am

Sorry Leanne, I think the metal hardness testing machines were in a different part of the factory. We worked in a self contained unit at the back of the main factory and the hardening shop. I think Mayjan might be able to answer your query but I have not seen her on here recently?  |

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

Mick Strong

Coventry

|

4 of 16

Thu 26th Sep 2013 6:13pm

Looks like a tool and cutter grinder, used for re-grinding gear hobs.

|

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

scrutiny

coventry

Thread starter

|

5 of 16

Fri 27th Sep 2013 8:17am

Hi Mick, almost right, it is a "Periform Grinder" used for grinding gear shaving cutters. Tolerance was one-ten thousand of an inch, there were three different dressers for it to produce all manner of different profiles on the teeth of the cutter.  |

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

Mick Strong

Coventry

|

6 of 16

Fri 27th Sep 2013 7:04pm

Was that the blade type cutters for straight bevel gears?

|

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

scrutiny

coventry

Thread starter

|

7 of 16

Sat 28th Sep 2013 6:53am

A gear shaving cutter was used for shaving the correct form onto mass produced gears, ie. the gearbox in your car. Every gear that is made has to be shaved by a cutter to allow it to mesh properly. A shaving cutter could shave up to 50,000 gears before needing re-grinding to sharpen it. All cutters had different forms ground on them and that is where the skill came into setting the periform grinder for grinding them.

On my machine I had a special dresser for producing intricate forms on the grinding wheel. One gear shaving cutter made for shaving one gear that went into a ship could take up to three weeks to grind because of the high tolerance. This cutter was then thrown away as this gear, 12ft in diameter, after shaving, was built into only the one ship.

This is part of one but they came in all sizes and angles with different numbers of teeth on them. From a spur to 56 degrees.

|

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

|

Mick Strong

|

8 of 16

Sun 29th Sep 2013 4:31pm

|

|

Mick Strong

Coventry

|

9 of 16

Mon 30th Sep 2013 8:31pm

On 9th May 2013 7:13am, scrutiny said:

Sorry Leanne, I think the metal hardness testing machines were in a different part of the factory. We worked in a self contained unit at the back of the main factory and the hardening shop. I think Mayjan might be able to answer your query but I have not seen her on here recently?

Hi, was this company run by a father and daughter? |

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

scrutiny

coventry

Thread starter

|

10 of 16

Tue 1st Oct 2013 8:07am

Hi, it was family owned but not by father and daughter, although I think a small factory up the road from us was. Cannot recall the name though. |

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

Mick Strong

Coventry

|

11 of 16

Tue 1st Oct 2013 3:00pm

Gears and Components?

|

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

johnbettany

Allesley

|

12 of 16

Fri 9th Feb 2018 12:56pm

On 8th May 2013 8:54pm, LdeMain said:

My dad used to do some work at PGM, he was self-employed but used to service and calibrate the metal hardness testing machines, his name was Steve de Main. I'd love to know if anyone remembers him!

Leanne

Hi Leanne, I worked in the Inspection Department from July 1970 until the summer of 1983. I used to work in the Standards Room and remembered your father. We had the Hardness Testing machine in the Standards Room and he used to come in about once a year to calibrate it. I think we had another one in the Inspection Area on the other side of the company. I used a MAAG gear testing machine to check the form of the shaving cutters that were produced in the Cutter Shop. John Smith used to be the Inspector in the Cutter Shop. Does anyone remember Graham? They were happy times and I consider those years to be the happiest of my working life.  |

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

Derrickarthur

Coventry

|

13 of 16

Fri 9th Feb 2018 11:30pm

On 8th May 2013 8:54pm, LdeMain said:

My dad used to do some work at PGM, he was self-employed but used to service and calibrate the metal hardness testing machines, his name was Steve de Main. I'd love to know if anyone remembers him!

Leanne

I worked with Steve de Main at Dunlop for a couple of years before he set up in the hardness testing business. Remember him well. Blond hair & moustache. He played rugby. He always reminded me of Leslie Philips. |

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

johnbettany

Allesley

|

14 of 16

Tue 14th Aug 2018 9:47pm

Last week I picked up youngest daughter from work as her car was in for repair. She asked me to drop by her husband's work as she needed to see him. I was amazed that his place of work was on the old PGM site. It gave me the opportunity to have a look round. Trevor (my son-in-law) works as a cabinet maker in a unit that was once the canteen. There is another unit in what used to be the Cutter Shop. I'm not sure what the company in there makes. What used to be the Fitting Shop has been seperated from the Machine Shop by a wall. The unit now occupying the Fitting Shop has now been leased by Wickman Machine Tools, who are using it as a storage area for their old machines that have been bought back from various companies and are to be retro-fitted with CNC capability. The offices which were at the far end are still there and I think the area that used to be the Steel Stores is part of the Fitting Shop unit. I spent about an hour explaining to Trevor and his boss and also the two chaps working in the Wickman unit what was produced at PGM and what function each unit had. They were all really interested in the history of the site and what good times they were in the seventies and early eighties. It was also a happy trip down memory lane for me!

|

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|

KaTo

Canada

|

15 of 16

Tue 25th Jul 2023 10:34pm

Just came across this site, I do remember back in 1959-1960 as a young lad then, about a dozen men from Churchill- Redmond in Newcastle, moved down to Coventry to work at Precision Gears, all of these folks bought houses in the new development of Potters Green. I do not know what the affiliation was between PGL and Churchill Redmond, but I know all of these guys transferred down with the company. |

|

Industry, Business and Work -

Precision Gears and Machine Tools Ltd, Bodmin Road

|